Business sectors

Timber Trades

CAPTURE AND EXTRACTION OF POLLUTANTS IN THE TIMBER INDUSTRY

Sawmill, woodworking, carpentry, paper production, training school... Wood is at the heart of many professional activities. With 1 accident per year for 10 employees, and 2nd cause of work-related cancers (Source INRS), the sector is subject to strong regulatory constraints.

The wood processing method includes several stages that generate chips, dust and sawdust. Bucking, sawing, debarking, cutting, milling, planing, sanding, drying, chemical treatment, cleaning or even sharpening saws are among other sources of pollutant emissions dangerous for humans (respiratory discomfort, asthma, cancer). The presence of residual dust on machined wooden surfaces can also lead to quality defects.

Sawdust and dust produced by other processing methods entail a risk of fire and explosion in factories.

To avoid the risks linked to wood dust, the general ventilation of the premises is insufficient. It is necessary to capture the different sources of pollution, store, transport and evacuate them.

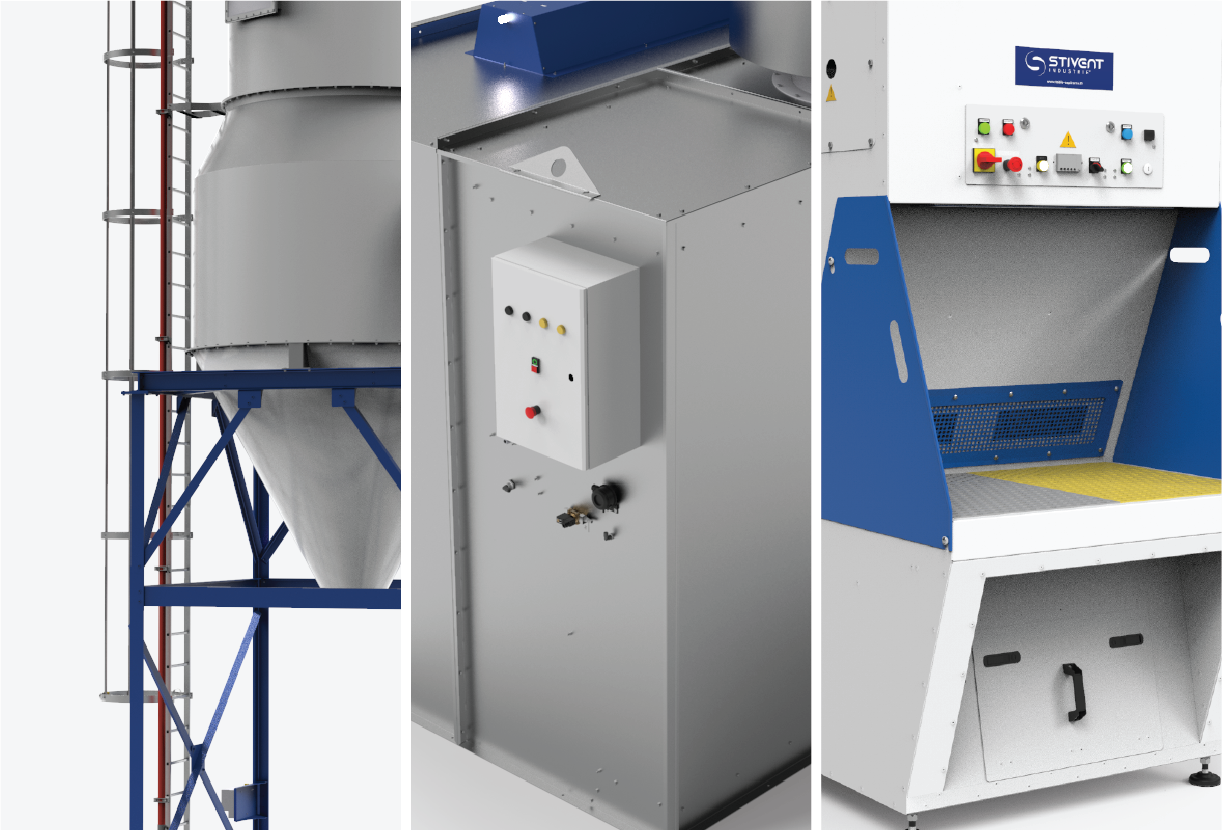

STIVENT INDUSTRIE® has therefore developed a complete range of equipment intended to collect these wood particles and revalue them on a secondary market (bark from trunks). They will allow you to meet all your needs in terms of:

- Capture and extraction of wood dust.

- Recovery of wood chips and sawdust.

- Fumes extraction due to sharpening saws.

- Capture of volatile wood components.

- Ventilation following the emission of glue particles, resin or adhesive.

FIND ALL OUR PRODUCTS

According to the type of pollutant and its source, find out the customised and/or standard solutions to meet all your requirements for industrial extraction, filtration and dust extraction.

For treatment in explosive environments, the equipment meets the ATEX standard.

For treatment in explosive environments, the equipment meets the ATEX standard.