Company

Industrial dust extraction

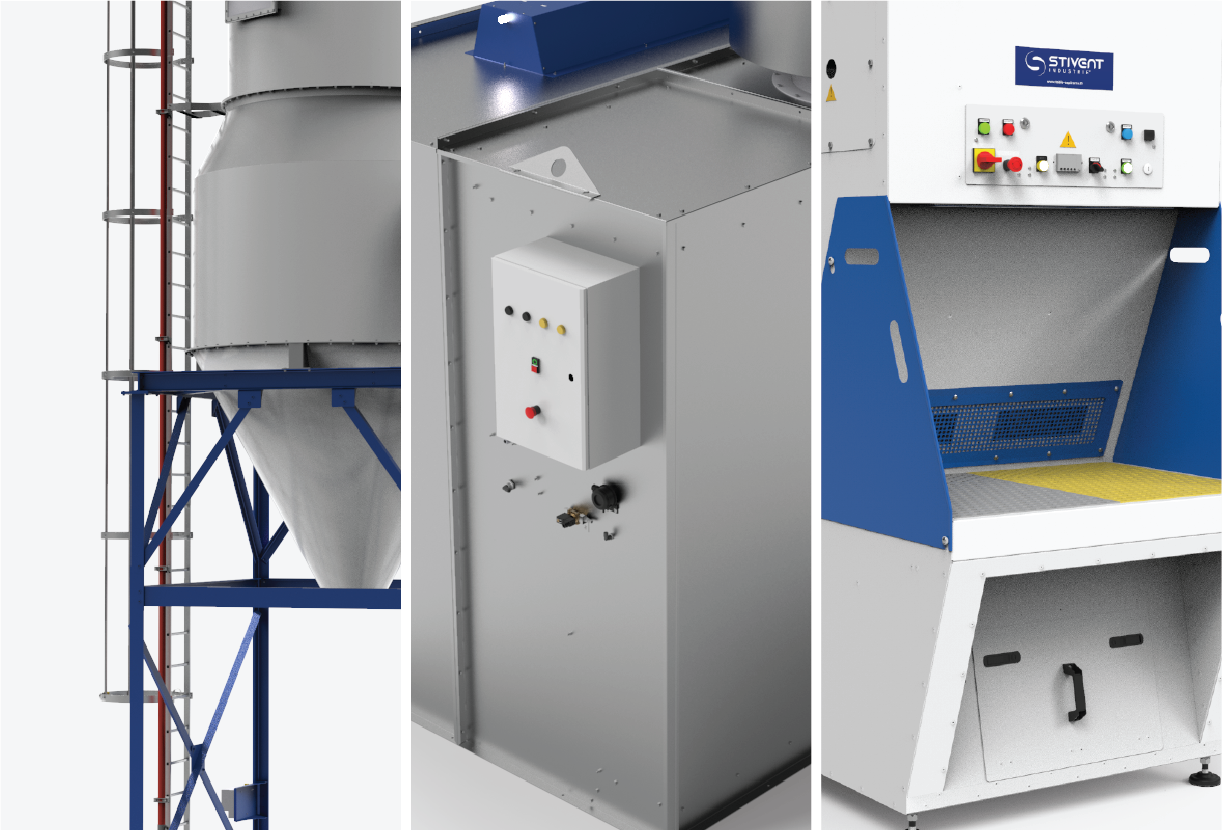

Chips, dust, particles... are real pollutants harmful to workers' health. STIVENT INDUSTRIE® studies, designs, manufactures industrial dust extraction systems to avoid certain contamination and thus contributes to improving working conditions.

Industrial activities as diverse as agro-cereals, food, timber, metallurgy, cement, resins,... emit chips, dust, particles... real pollutants harmful to workers' health. STIVENT INDUSTRIE® studies, designs and manufactures industrial dust extraction systems in France to avoid certain contamination. It thus contributes to the improvement of working conditions.

DID YOU KNOW?

According to the legislation, a dust is a solid particle with an aerodynamic diameter of not more than 100 micrometres or whose falling speed limit, under normal conditions of temperature is at most equal to 0.25 metre per second: Article R. 4222-3.

The occupational exposure limit values , i.e. the average concentration over an 8-hour period, are:

- total dust = 10 mg/m3 of air

- alveolar dust = 5 mg/m3 of air

The occupational exposure limit values apply to all forms of dust (marble, flour, etc.), but the particular effects of some of them justify the existence of lower limit values (wood, asbestos, silica, etc.): Article R. 4222 -10 of the Labour Code.

Dusts are very fine solid particles which remain in suspension in the air and whose level of penetration in the organism, by the pulmonary route, depends on their size.

|

Dust size |

Effects |

|---|---|

|

From 10 to 100 microns |

Also called “total dust”, this dust is retained at the level of the nasal cavity. |

|

From 5 to 10 microns |

Dust which penetrates into the trachea, the bronchi, then the bronchioles. They can be spat out or swallowed in the oesophagus; but if the dustiness is too high, it will go to the cells. |

|

0.5 micron |

Very fine dust which settles on the alveoli in the lungs. |

|

Below 0.5 micron |

Dust behaves like a gas in the body and follows pulmonary ventilation. |

Sources: Ministry of Labour

It is therefore easy to understand the importance of preventing the risks that dust can generate both for health and for safety (risk of fire and explosion).

STIVENT INDUSTRIE®, RECOGNISED EXPERT IN INDUSTRIAL DUST EXTRACTION

Industrial fan, baghouse dust collector, cartridge dust collector, cyclone, cyclofilter, downdraft tables… what “smart” choice to make? for what type of industry? how much activity? which dimensioning?...

Tip # 1 to remember, if there were only one, is to absolutely avoid the use of the blower to blow away dust without nearby suction means to avoid dispersion. It might make you smile, but... unfortunately, it's an "easy" gesture.

MEASURING THE WORKING ENVIRONMENT

For any dust collection installation as close as possible to the source of emission, it is essential to conduct a careful study of the working environment, air treatments, and the nature of the pollutants to be sucked.

An efficient and optimal industrial suction solution takes into account the client problem to be solved in its industrial environment. At STIVENT INDUSTRIE®, we take into account all the measurement of the working environment:

- Nature of pollutants - wood, glass, metal, resin, or flour dust, etc

- Dust properties and particularities - size, particle size, humidity, temperature, friction, explosiveness...

- Workstation to be equipped and installation surface available for the extraction system...

DUST EXTRACTION DEVICE

Any installation of a dust extraction device follows a well-established scheme:

- Capturing dust as close as possible to the machining heads (any axis/any speed/reduced space) without interfering in the operator's working space.

- Transporting dust taking into account the densities of the particles, times and transport speed (rules and aeraulic dimensioning).

- Filtering dust: this is the most delicate and technical operation that cannot be improvised. It responds to very precise aeraulic calculation rules which condition the adequate filtration system (cyclone, fan, unclogging, pressure/vacuum, type of filter, etc.).

- Collecting dust for bagging, or evacuation towards appropriate buckets. At this stage, the extracted waste can experience a new life cycle, sometimes with a step of revalorisation of chips or particles from “precious” materials, or use for sandblasting for example…

From study to realisation through manufacturing STIVENT INDUSTRIE® is an all-in-one contact for your projects.

In addition to this approach and these essential steps, since 1962 STIVENT INDUSTRIE® has supported its clients during the installation, start-up, and controls to certify the compliance of the device put in place. Recommendations for use and awareness of regular checkpoints are transmitted so that each client can independently monitor the optimised operation of their installation (fouling of filters, measurement of air flow rates, filtration measurement, etc.) and guarantee them thus the durability of its industrial dust extraction equipment.

EXPLOSIVE RISKS!

All our industrial dust extraction systems are designed to meet a double objective: improving the air quality at work and the working conditions of operators according to the recommendations of INRS, CARSAT and that in the greatest compliance with ATEX standards.

The risk of fire and the risk of explosion are fully understood from the start of our studies, or even pre-studies.

More than 25% of STIVENT INDUSTRIE® staff is ATEX level 2 certified. From the design office to the maintenance, including the engineering office, the quality office and even the sales staff - all have acquired the ATEX certification level known as “EXPERTS”, allowing them to deal with skills for all design, production, installation and maintenance tasks for dust extraction and industrial air filtration devices in explosive atmospheres.

For any question on industrial dust extraction or request a quote, contact us on (+33) 05 49 50 41 91 or via our contact form.