Products

Spray booth

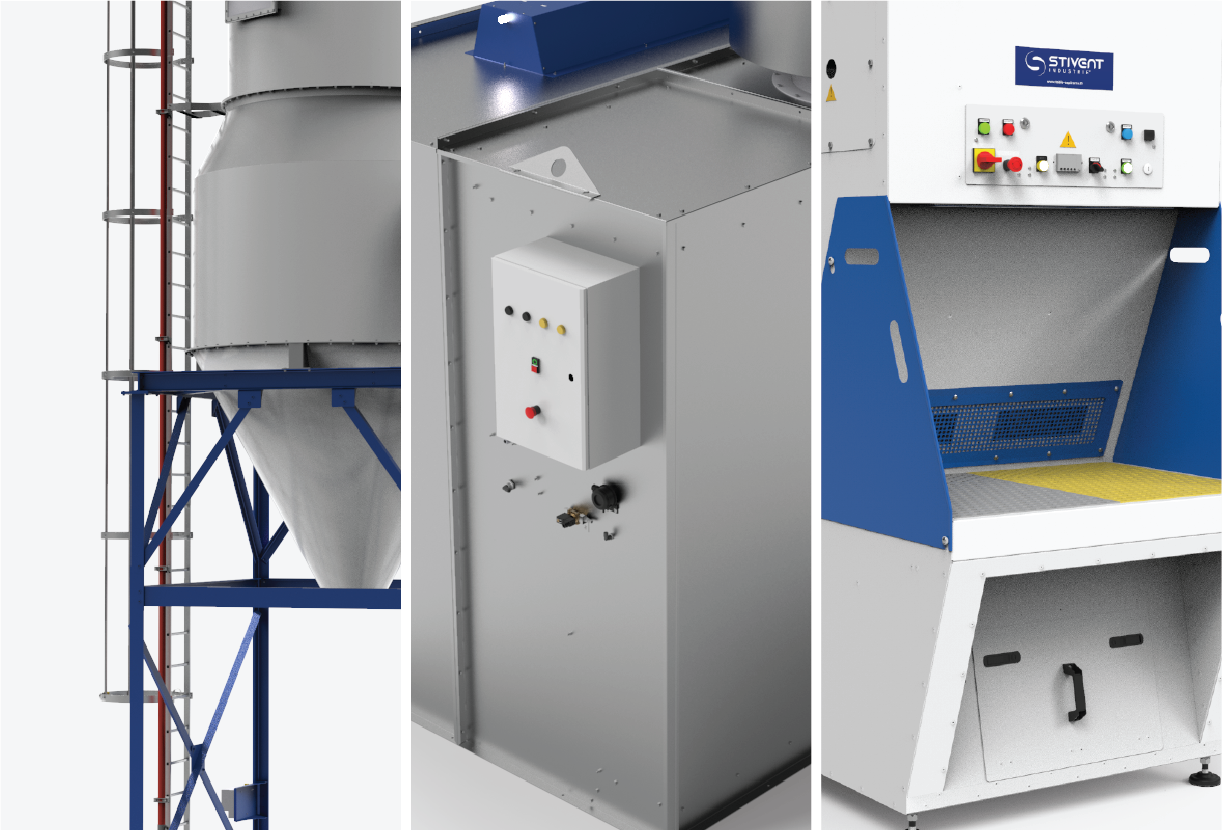

EXTRACTION OF PAINT AND VARNISH

Paints and varnishes commonly used in industry can present risks of poisoning, fire and explosion. To protect the health of operators and protect the working environment, we recommend installing a suction and ventilation system to sanitise the air.

Our booths are designed to allow an outdoor discharge to the wall or roof. The sprayed excess particles are sucked towards the filter by the horizontal air flow coming from behind the operator (average minimum speed of 0.5 m/s). This air flow protects the operator and prevents the spread of pollution to the surrounding environment.

The fans provided comply with ATEX ZONE 1 standards with ATEX motors.

The fans provided comply with ATEX ZONE 1 standards with ATEX motors.

8 times out of 10, the chosen solution is selected from our range of products designed to suck Volatile Organic Compounds, such as paint, glues, polyurethane foam, edible liquids.

However, as a manufacturer with a design office, STIVENT INDUSTRIE® is able to modify its catalogue of standard products by adapting it to your specific requests and problems: INOX version, compatible for food, discharge to the workshop, etc.

RANGE FEATURES

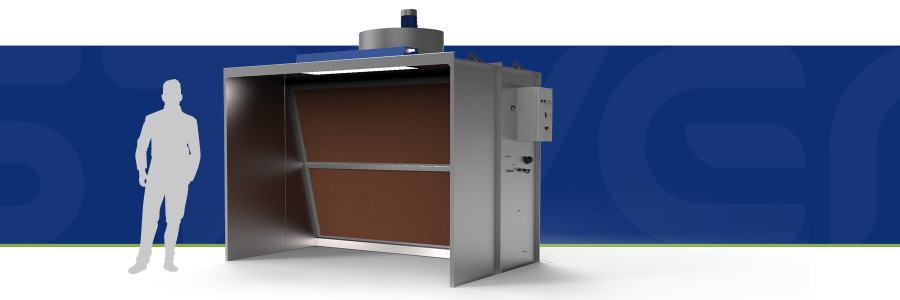

Our spray booths are available in 3 sizes: 2, 3 and 4 metres.

For greater optimisation, each booth is modular and composed of two elements:

Base

The core of the booth is made up of:

- A fan

- A frequency converter to optimise the suction performance to combine capture efficiency and energy efficiency

- The filtering portion

Extensions and options

- Bare, without additional lighting, very simple

- Lighting for greater user comfort

- Various servo-controls

- Custom accessories

| Download files |

|---|

| Spray Booth - Download data sheet and options (French) |