Products

Rockster

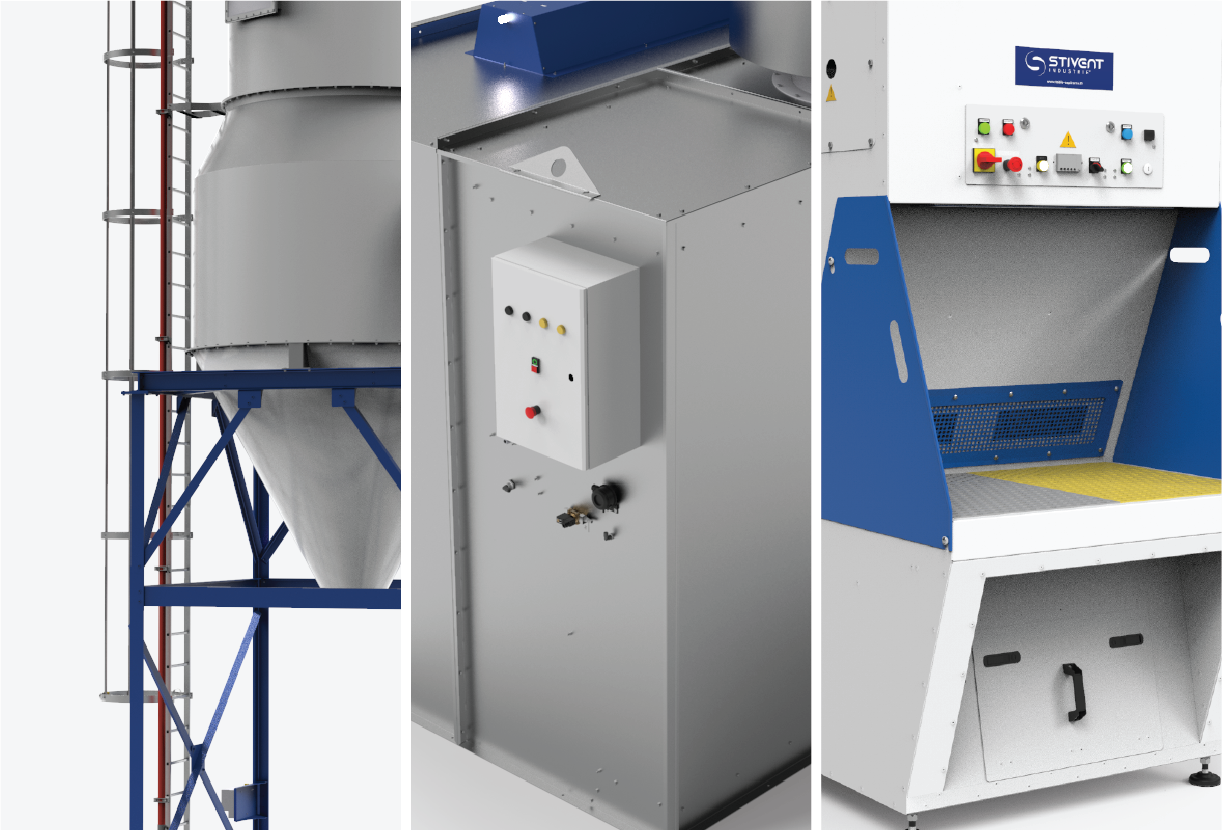

ROCKSTER: THE 3rd GENERATION OF ROCK WOOL BLOWER

In less than a cubic metre, you have before you a summary of the core business of STIVENT INDUSTRIE®: suction and expulsion of air at "pulsed" speed.

For information, for over 20 years, in partnership with ROCKWOOL, STIVENT INDUSTRIE® has developed a machine for blowing rock wool in the roofspaces.

This economical, simple to install, blower system allows the thickness and regular density of the insulation to be deposited on each square metre to be treated.

The very first blower called ROCKVENT was replaced fairly quickly by the ROCKSTER 1 recognisable by its red plastic fairing.

ROCKSTER 2 replaced the Rockster 1 sometime later because it had a longer lifespan.

And since 2014, the ROCKSTER 3 has been the STAR of rock wool blowers.

Power and profitability, its blowing rate has been increased by 50%, which allows the installation of the insulation even faster.

Practical, a new swivel wheel placed at the front of the machine facilitates effortless movement. The ergonomics of the suction nozzle have been improved with the installation of a strap with a shoulder strap and a more comfortable handle when gripping.

Compact and Ergonomic, its dimensions 1032 X 680 X 905 mm and its flexible piping make this blower a compact tool that does not take up too much space on a site.

Safe, it is equipped with a radio control which facilitates dialogue between operators and simplifies teamwork. A first operator located in the roofspace with the remote control gives an impulse on the “start” button; a beacon lights up giving the order to the operator at the bottom to start the machine. When the operator in the roofspace no longer needs to pulsate the rock wool, he presses the "stop" button which has the effect of turning off the beacon and stopping the fan motor of the machine.

Note: the remote control does not allow the engine to be started for safety reasons.

Low noise level, at both suction and discharge the noise level is around 75 Db (A).

Robust, without specific maintenance, ROCKSTER 3 blowers are now welded by a robot, which increases reliability. In addition, all the machines are tested before delivery.

Durability, spare parts are available to compensate for normal system wear and allow a longer service life for the ROCKSTER.

AD HOC packaging, a tailor-made packaging and conditioning has been developed for the deliveries of each blower with specific settings to ensure serene delivery and no unpleasant surprises when unpacking.

Thanks to the mechanical blowing of the ROCKSTER 3, insulating so-called “lost” or inaccessible roofspaces becomes child's play.

To find out more about ROCKSTER blowers, contact us on 05 49 50 41 91 or via our contact form.

| Download files |

|---|

| Rockster - Download instructions (French) |