Business sectors

Plastics

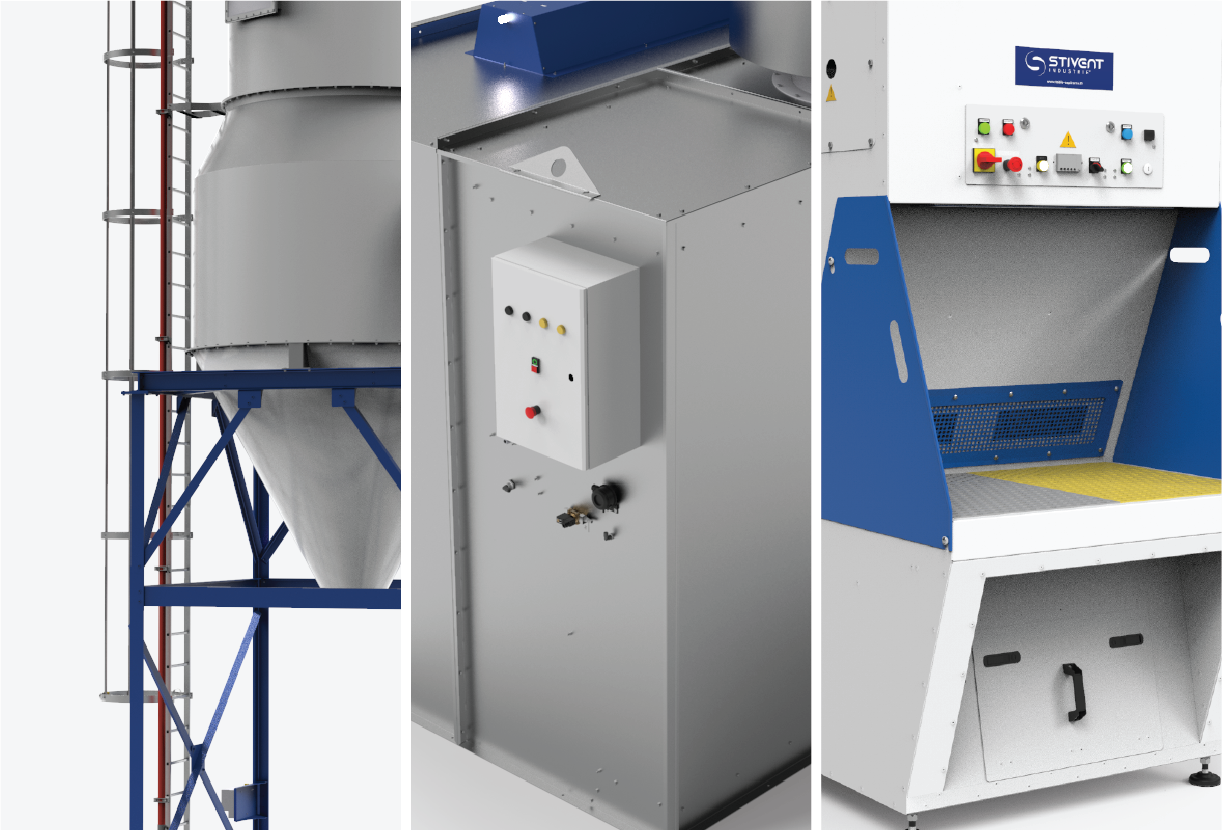

EXTRACTION AND COLLECTION IN PLASTIC AND RESIN INDUSTRY

Plastic is a synthetic polymer used for the manufacture of a large number of products such as toys, cables, packages, construction, electronics, coatings, etc. Made from petrochemical compounds, plastic is sent to manufacturers in the form of granules or powder.

Whether by injection, thermoforming, extrusion-inflation or extrusion-blowing, rotational moulding or compression, the plastic processing methods are most often accompanied by the release of many pollutants (= fumes, dust, gas) toxic and harmful for operators and the environment.

Plastic machining operations also produce waste which must be eliminated progressively in order to guarantee production rates in line with the company's productivity and quality objectives.

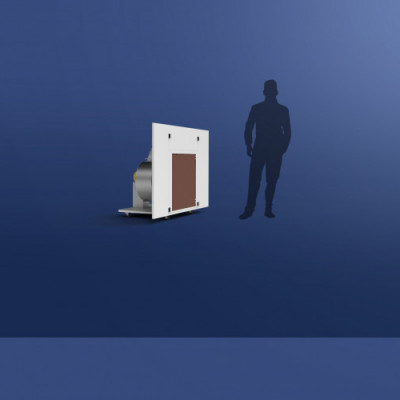

To limit the risks of pollution throughout the transformation of plastic into finished product, STIVENT INDUSTRIE® advises you and offers you tailor-made or standard equipment designed to meet your needs in terms of:

- Extraction of gases and vapours

- Capture and filtration of dust

- Recovery of production waste

- Ventilation and sanitation of the atmosphere in the workplace

- Cleaning of production lines

- General ventilation

FIND ALL OUR PRODUCTS

According to the type of pollutant and its source, find out the customised and/or standard solutions to meet all your requirements for industrial extraction, filtration and dust extraction.

For treatment in explosive environments, the equipment meets the ATEX standard.

For treatment in explosive environments, the equipment meets the ATEX standard.