Design department

Oil mists

SUCTION AND TREATMENT OF OIL MISTS

Oil mists and fumes generated during machining operations are harmful to the health of operators and the environment.

In fact, in the metallurgical industry, cutting fluids are used to cool and lubricate materials during machining operations. They make work easier and help improve the life span of the tool.

In many processes such as drilling, grinding, sharpening and other metalworking activities, the fluids used associated with the rapidly rotating parts form a mist made up of fine droplets. These oil mists and fumes then disperse into the air. Operators are then exposed to the risks of inhalation and/or ingestion.

RISKS AND HARMFUL EFFECTS

Composed of cutting fluids, thermal degradation products and solid particles from machined materials, oil mists are responsible for several phenomena such as:

- Formation in the workshop of a bluish fog

- Creation of "hot" or "burnt" oil odours

- The formation of greasy films on floors, work surfaces and all surfaces in the workshop

- Pathologies of the skin and respiratory tract in operators

When metalworking fluids form an oil mist, the larger droplets can enter the nose and trachea and then be swallowed. The finest droplets can settle in the lungs and severely irritate the eyes, nose and throat. They are likely to cause dermatitis, skin cancer, pneumonia,..., diseases and conditions that can be recognised as occupational diseases.

By depositing on machines, these oil mists also cause premature wear of your equipment and risk of resulting in high maintenance costs.

On the floor, they involve the risk of slip and fall accidents and consequently potentially work stoppages.

Finally, without maintenance of machinery and the working environment, oil mists increase the risk of fire. Hygiene problems may also arise from the growth of bacteria and other moulds.

For all of its reasons, manufacturers must also comply with article R. 4222-10 of the Labour Code which stipulates that in premises with specific pollution, the average concentrations of total and alveolar dust must not exceed 10 and 5 mg/m3 of air over a period of 8 h.

THE SOLUTION

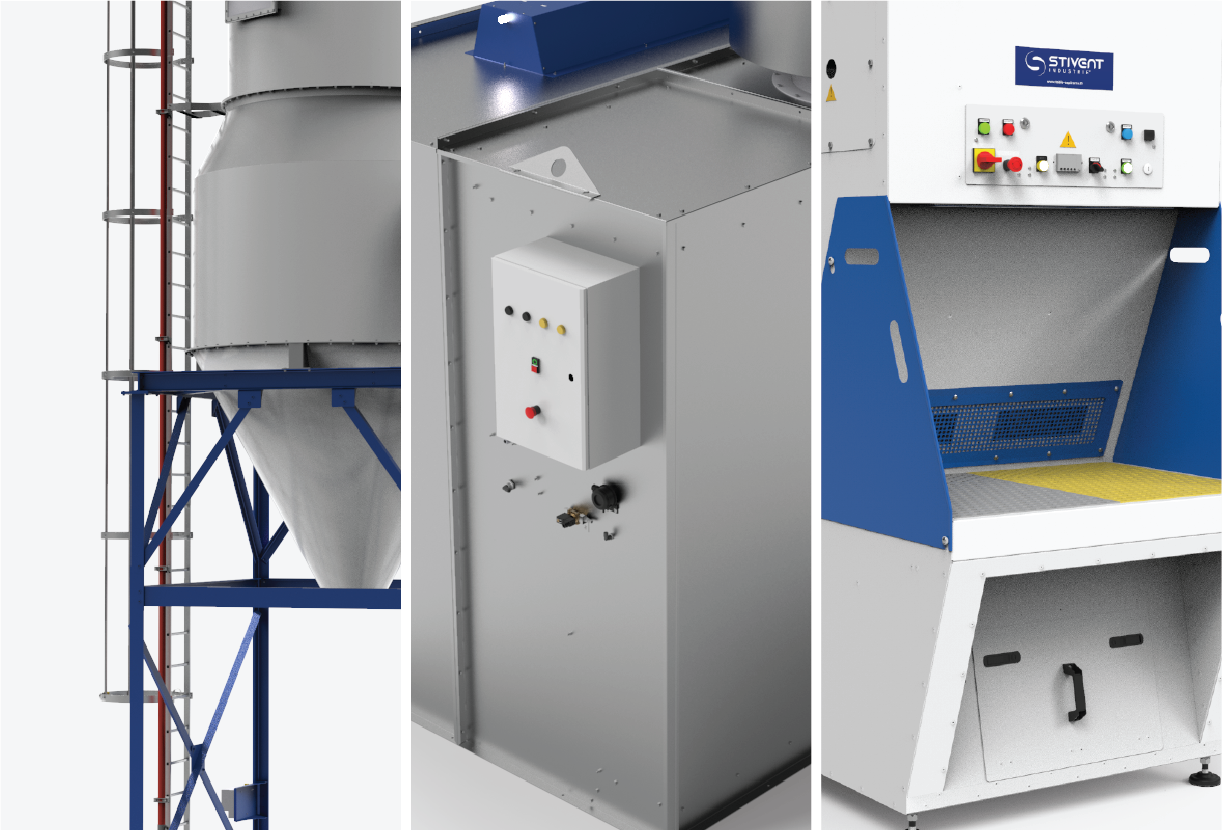

The capture and treatment of oil mists is a major issue in the metal processing sector in order to maintain a clean, healthy workspace and protect workers. To avoid all these risks and sanitise the air, it is therefore essential to set up collective and individual prevention measures to capture, transport and treat oil mists. Thanks to its various filtration and separation technologies, STIVENT INDUSTRIE® is able to assist you in the treatment of oil mists by studying the best possible solution in your industrial process.

Machine or tailor-made capture, separation or filtration, we will integrate your constraints at the heart of our study. For treatments in explosive environments, our equipment meets the ATEX standard. Using the suction and filtration systems implemented by STIVENT INDUSTRIE®, the risk of fire is reduced, and operators are effectively protected while optimising your production tools.

Machine or tailor-made capture, separation or filtration, we will integrate your constraints at the heart of our study. For treatments in explosive environments, our equipment meets the ATEX standard. Using the suction and filtration systems implemented by STIVENT INDUSTRIE®, the risk of fire is reduced, and operators are effectively protected while optimising your production tools.

Do you need support for oil mist treatment? Contact us on (+33) 05 49 50 41 91 or via our contact form. Together, we'll find an efficient solution.