Products

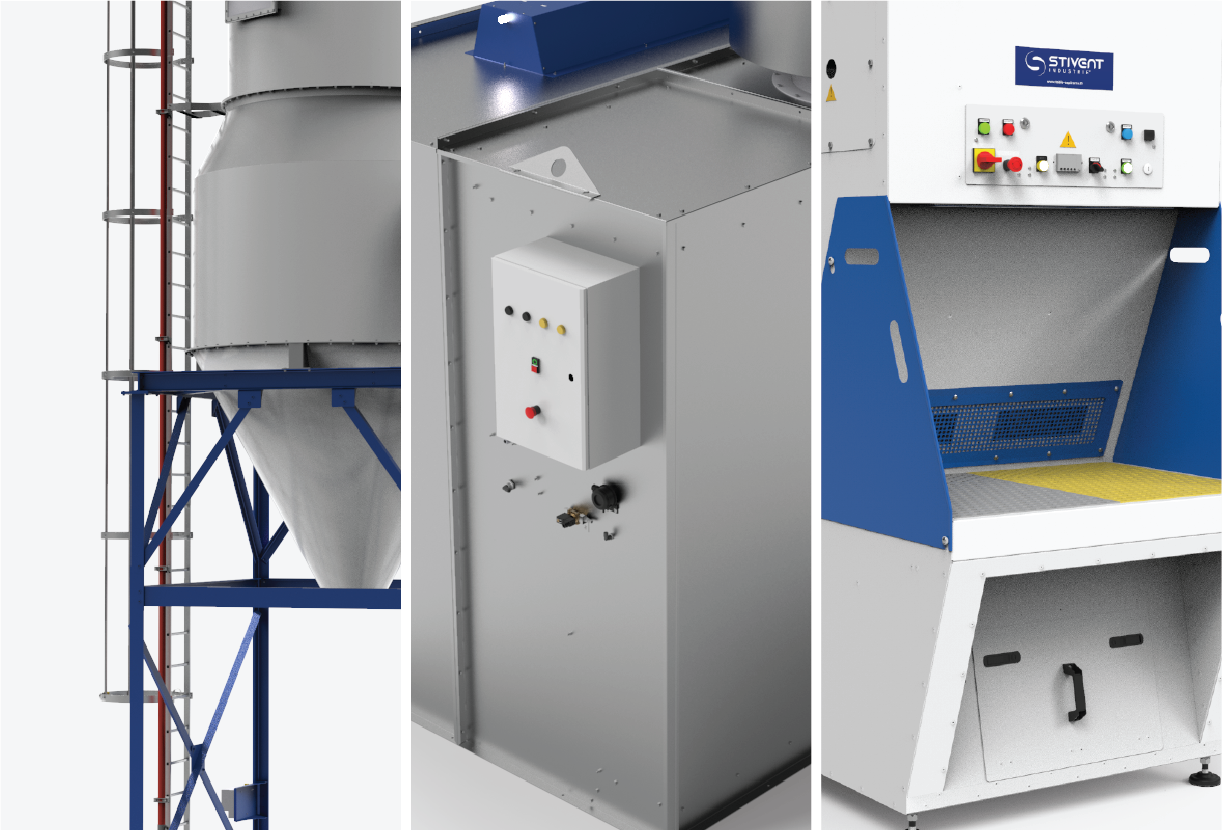

Cyclofilter

CYCLOFILTER FOR THE TREATMENT OF LARGE DUST VOLUMES

AUTONOMOUS - RESISTANT - SECURE - RELIABLE - EFFECTIVE

STIVENT INDUSTRIE® designs and develops cyclofilters to improve working conditions during high dust concentrations.

As a filtration element, the cyclofilter is mainly used to purify large volumes of air heavily loaded with dust and chips. It can be installed in industrial sectors (chemicals, cosmetics, construction, pharmaceuticals, plastering, etc.) generating dry dust.

They can also be used to prevent pollution problems on the premises or to intervene in a production process. Indeed, the evacuation of dust and chips generated by a machine tool improves its production.

Our devices are intended to treat explosive dust and are therefore equipped with protection elements imposed by ATEX legislation.

Effective, no dust escapes it over a flow rate range from 6,500 to 130,000 m3/h.

Adaptability, thanks to our design office all our cyclofilters are custom-made and cover all your needs. Options are also available to further improve their use.

Convenience, their design spaces the interventions for filter maintenance.

Reliability, solution proven with industrial grade components, a product designed to last.

Applications: Wood, cement, resins, dust and various chips

Options :

- Different modes of dust recovery

- Conical bottom or flat bottom

All the cyclofilters manufactured by STIVENT INDUSTRIE® have been tested in digital simulation and of course long-time proven in practical use by our clients.

All of our products are customisable and/or scalable according to your needs and technical constraints. Contact us on (+33) 05 49 50 41 91 or via our contact form. Together, we'll find a solution.

OPERATION

The cyclofilter combines two technologies for the separation of air and matter:

Cyclonic pre-separation: the air charged with particles arrives in the cyclofilter through a tangential air inlet and separates from its heaviest elements thanks to centrifugal force. The finest dust is captured in the filter section by the filtering elements. Clean air is returned to the factory or released to the outside.

Bag filtration: the dust residue is then subjected to the bag filter medium test which completes the filtration process. A self-cleaning system facilitates electro-pneumatic cleaning of the filter media. The latter ensures suction and filtration performances.

After the unclogging phase, the dust falls by gravity into the container through the hopper. The dust thus collected is evacuated to a bucket or any other storage system.

Do you want to equip yourself with a cyclofilter? Contact us on (+33) 05 49 50 41 91 or by email at contact@stivent.fr. We will find together an efficient solution in line with your requirements.