Products

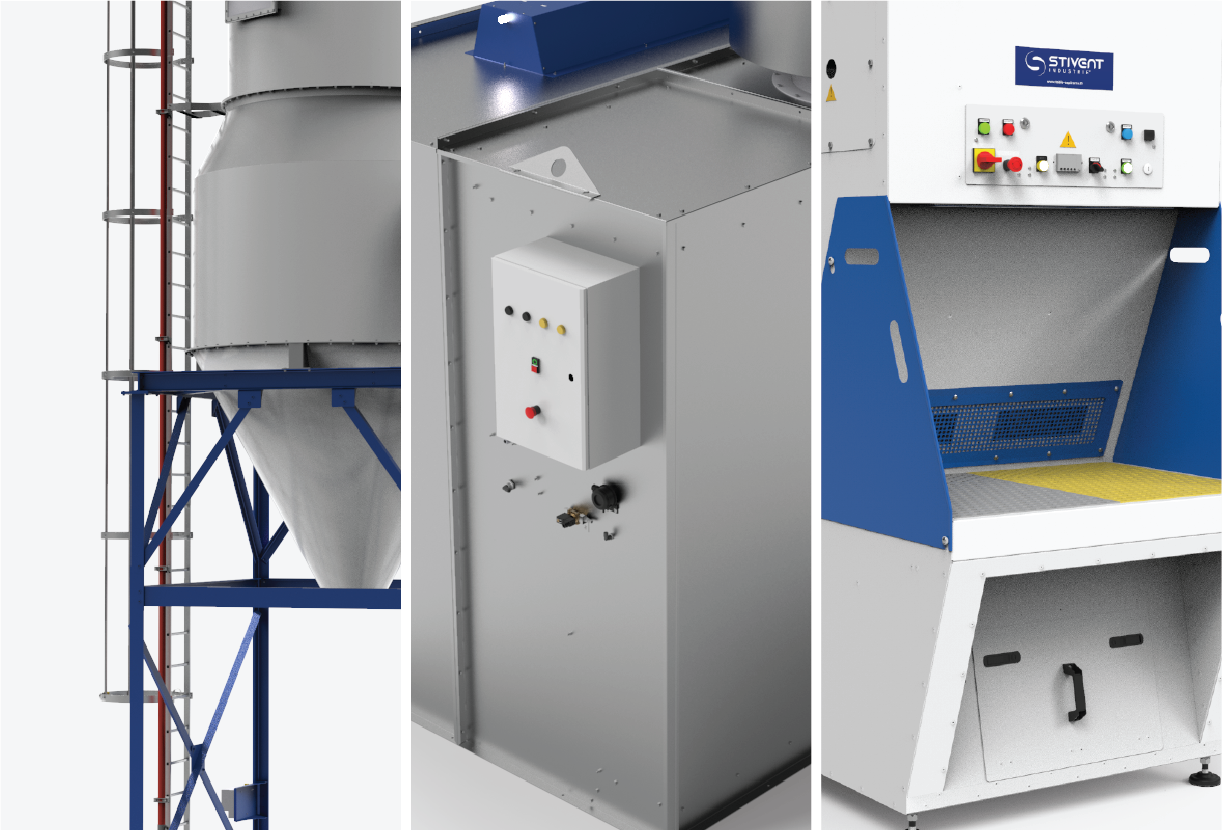

BPM-type downdraft table

BPM DOWNDRAFT TABLE FOR DUST AND PARTICLE SUCTION

Dusts and particles present in the workspace during polishing, grinding, deburring, rectification and adjusting operations can pose health risks to workers.

To guarantee the quality of the air in work premises and preserve the health of operators, STIVENT INDUSTRIE® has developed the BPM downdraft table.

The STIVENT INDUSTRIE® Polishing and Grinding Bench has been designed specifically for all users of bench grinder; mainly intensively.

BPM is the first intensive, autonomous solution with high performance filtration for users of bench grinders.

A bench grinder, integration of which has been optimised for ergonomics and ease of use, is directly equipped to capture the dust and sparks emitted at high speed when the tool is used.

An air space forming a protective light curtain has been integrated to avoid the effects of particles returning at high speed to the operator.

Once captured, the dust is filtered up to 99.9% thanks to a double filtration stage. For longer life, the first stage is cleaned automatically by a jet of compressed air.

The BPM downdraft table also benefits from a low noise level, it is less than 70 dB (measured at the work surface excluding the bench grinder in operation).

As standard model, it is equipped with a control box, a double suction zone, flexible side cheeks and displacement wheels.

As an option, we can offer you: customised painting, local exhaust ventilation, retractable side curtains, specific cartridges, modular lighting, soundproof casing, etc.

For the treatment of materials at risk of explosion, the equipment meets the ATEX standard.

For the treatment of materials at risk of explosion, the equipment meets the ATEX standard.

All our tables are customisable and/or scalable according to your needs and technical constraints. Contact us on (+33) 05 49 50 41 91 or via our contact form. Together, we'll find a solution.

MODEL FEATURES

Ergonomic, the BPM downdraft table allows working in a standing or sitting position. Thanks to its handles and wheels, it is easy to move.

- Overall dimensions in mm (D x W x H): 1400 x 850 x 2010

- Power kW: 1.5

- Average minimum speed m/s: 2.5

- Maximum flow rate: 2690

DISCOVER IT ON VIDEO: