Products

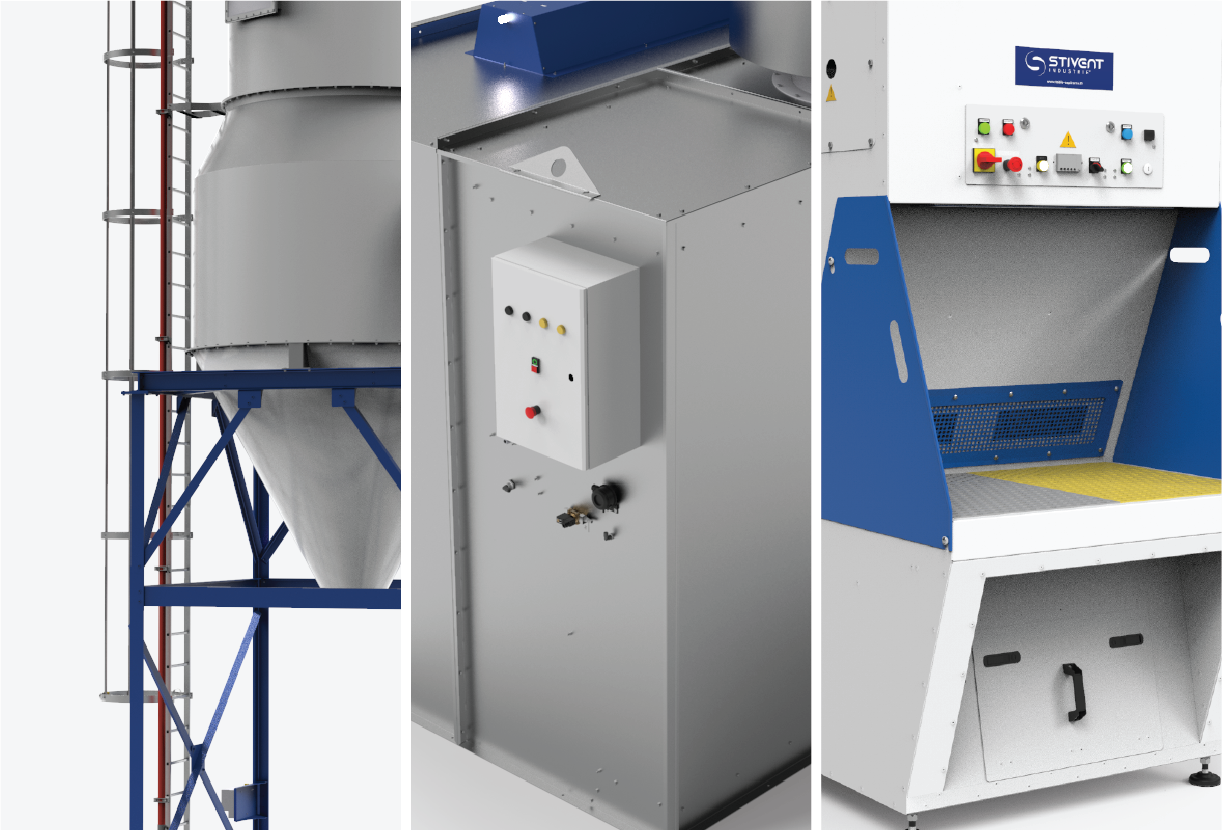

Baghouse dust collector

BAG FILTER FOR LARGE VOLUME INDUSTRIAL DUST EXTRACTION

PERFORMANCE - ECONOMY - SIMPLIFIED MAINTENANCE - LONGEVITY

Industrial dust extraction equipment, the baghouse dust collector stands out for its ability to manage high volumes of exhaust air thanks to its FDAPC or ROBOCYCLAIR type filters. Indeed, like a cartridge dust collector, the bag filter is equipped with a cleaning system that can be pneumatic or mechanical.

The FDAPC are filters fitted with a compressed air injection system causing the detachment of dust cake for a longer lifespan of the bags.

ROBOCYCLAIRS are bag filters with mechanical cleaning by vibrators. The set of bags is mounted on a semi-mobile device which is vibrated as soon as the machine is stopped. This system is more economical than the compressed air system. Its operation is optimal for coarse particles

Compatible with ATEX dust treatment, these filters are a guarantee of safety and efficiency for manufacturers. They deliver optimal performance and efficiency, while meeting the most demanding standards on air quality.

Compatible with ATEX dust treatment, these filters are a guarantee of safety and efficiency for manufacturers. They deliver optimal performance and efficiency, while meeting the most demanding standards on air quality.

Effective, no dust escapes the baghouse dust collector thanks to its flow capacity from 6,000 to 45,000 m3/h (180 bags for FDAPC).

Economical for the planet and for industries, low consumption of compressed air for the FDPAC, and controlled maintenance costs. The compressed air injection system allows cleaning the filter elements thus optimising their longevity and reducing maintenance costs.

Efficient, capable of filtration performance up to 99% while respecting environmental discard rates.

Adaptable, it is possible to bring in several separate networks, and to place a recovery network after the lock to convey the dust towards a storage by buckets. In addition, these industrial dust collectors can operate either under pressure or under vacuum depending on the position of the fan in the network.

Practical, they are designed as standard with inspection hatch on the hopper and internal setting(s).

Applications: Food, plastic, carbon, aluminium, wood, composite, etc., the bag filter is capable of treating multiple dust materials depending on the filter medium with which it is equipped, regardless of the type of operations performed (sanding, grinding, planing, sawing, bagging, weighing, etc.).

All the products manufactured by STIVENT INDUSTRIE® are customisable and/or scalable according to your needs and technical constraints. Contact us on (+33) 05 49 50 41 91 or via our contact form. Together, we'll find a solution.